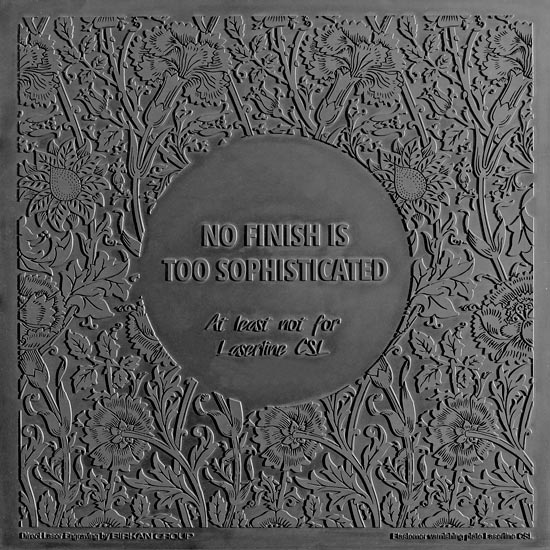

Laser engraved elastomer varnishing plates

From soft touch to textured varnish and from complicated patterns to delicate fonts, it's the perfect solution for even the most sophisticated finishes.

Product Overview

Contact

Please send your request or file (up to approx. 10 mb) to:

For larger files, we offer an upload option via FTP (access data on request).

Product information

- Flyer Laserline range

- Data sheet Laserline EPDM CSL

Order, request, file transfer

What is Laserline EPDM CSL?

Laserline EPDM CSL is an elastomer varnishing plate, consisting of an EPDM layer and a polyester carrier. The stencil is produced by direct laser engraving.

Both the robust material, perfectly suited for varnish transfers, and the high-precision laser process offer unique advantages in their combination. Therefore, this plate is clearly superior to conventional photopolymer varnishing plates in several respects.

The essential features at a glance:

-

Application range:

Laserline EPDM CSL is basically suitable for any type of varnish – both aqueous and UV. However, the stencil's true strengths are particularly evident where conventional plates have a tendency to fail, for instance with textured, high-gloss, soft touch or other special-effect varnishes. This is partly due to the excellent transfer characteristics of the elastomer material, which manages with less varnish. -

Durability:

Laserline EPDM CSL is resistant to chemicals and does not swell. It is also insensitive to breakage and scratching – and thus the ideal varnish plate for repeat runs. -

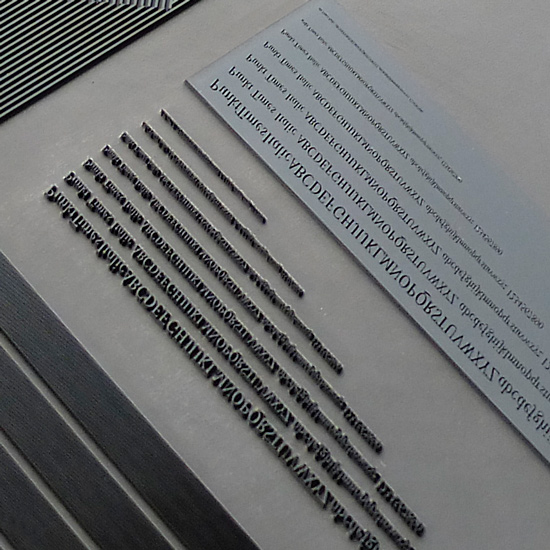

Fine lines, fonts, or patterns:

The maximum resolution of 5080 dpi opens up a completely new dimension in stencil design. The direct laser engraving technology moreover allows a maximum of edge sharpness. Thanks to the seamless digital production process, the original data is converted in the plate 1:1. -

Stripping performance:

The printing surface is not only laser engravable, it's also strippable. You can therefore combine complex details and large surfaces on a single plate. Environmentally friendly technology:

No solvents or other chemicals are used. The cleaning of the lasered plate from the ash residue is only done with water and biodegradable cleaning agent. The energy input is also lower, as the manufacturing process involves only two stages (lasering + washing).

Formats, thicknesses and alternative versions

-

Available formats:

– All common offset formats up to 7B format

– Largest laser engravable format: 1650 x 1300 mm -

Available thicknesses:

– 1.15 mm / 1.35 mm (on stock)

– 1.70 mm (on request) -

Alternative version:

– CSL “F”: Surface with firm adhesion (not stripable); only in 1.15 mm