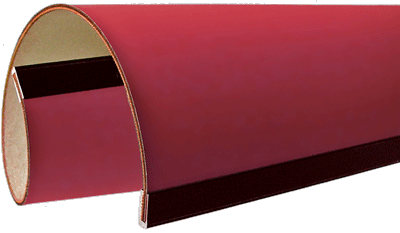

BIRKAN 4300 UV

(LED) UV blanket with innovative carcass technology

Developed for dedicated UV printing, BIRKAN 4300 UV uses next-generation technology to ensure exceptional durability, stability, and print performance.

The blanket is characterised by high smash resistance and advanced carcass technology, offering robust performance for consistent, high-quality prints. This ensures a longer life and reduces the total cost of consumables.

In addition to its excellent ink transfer properties, the micro-ground EPDM surface is characterised by particularly good resistance to swelling and embossing. It is not only abrasion and chemical resistant, but also extremely easy to clean. Furthermore, the surface ensures excellent sheet release and edge marking resistance.

The enhanced carcass construction includes a closed-cell compressible layer. It ensures uniform print pressure in a wide range of press configurations and across all format sizes, excellent rebound characteristics and smash resistance.

Last but not least, the high-quality woven fabric ensures high stability, robustness and durability due to its low stretch properties.

By extending the running time of the blanket in the machine, all these factors contribute to higher productivity and reduced overall costs in the printing process.

| Application Range: |

| Sheetfed offset • carton printing • high and low energy UV curing systems • metal printing |

| Compatibility with: |

| UV inks and washes • broad variety of substrates |

| Main features: |

| Effective, clean and precise ink transfer • excellent release characteristics • resistant against swelling • high smash resistance • quick rebound characteristics • easy to clean surface • high stability • high durability |

All Printing Blankets

Overview Product Range

Printing blankets, underpacking material, measurement instruments and press room accessories: Download here the brochure in English language (1,0 MB).

![]() Catalogo de productos offset (español)

Catalogo de productos offset (español)